China jumbo roll slitting rewinder machine sale quotes

- BAOSUO

- China

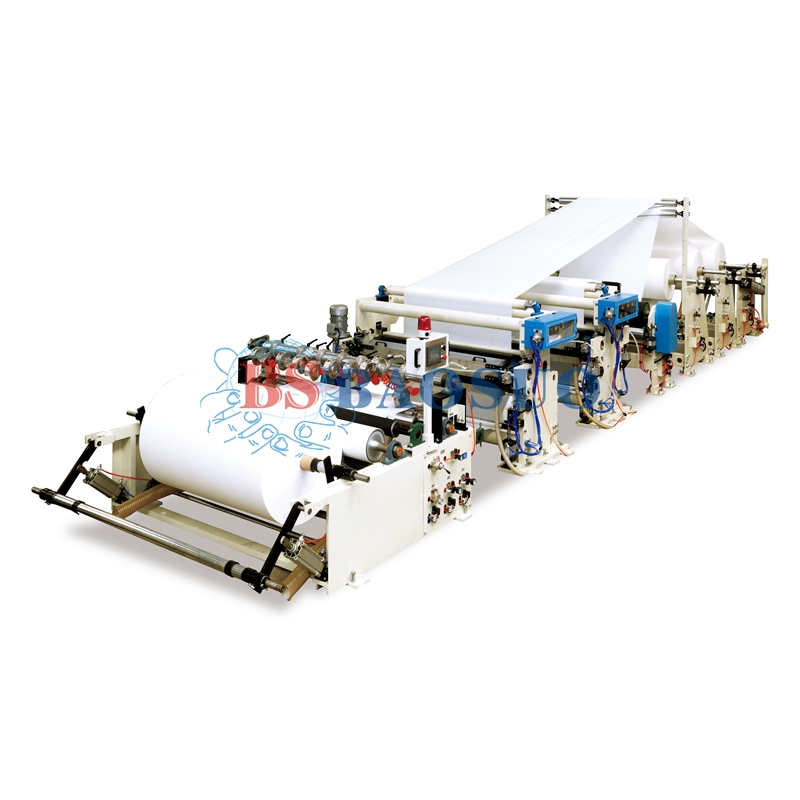

Brief introduction:

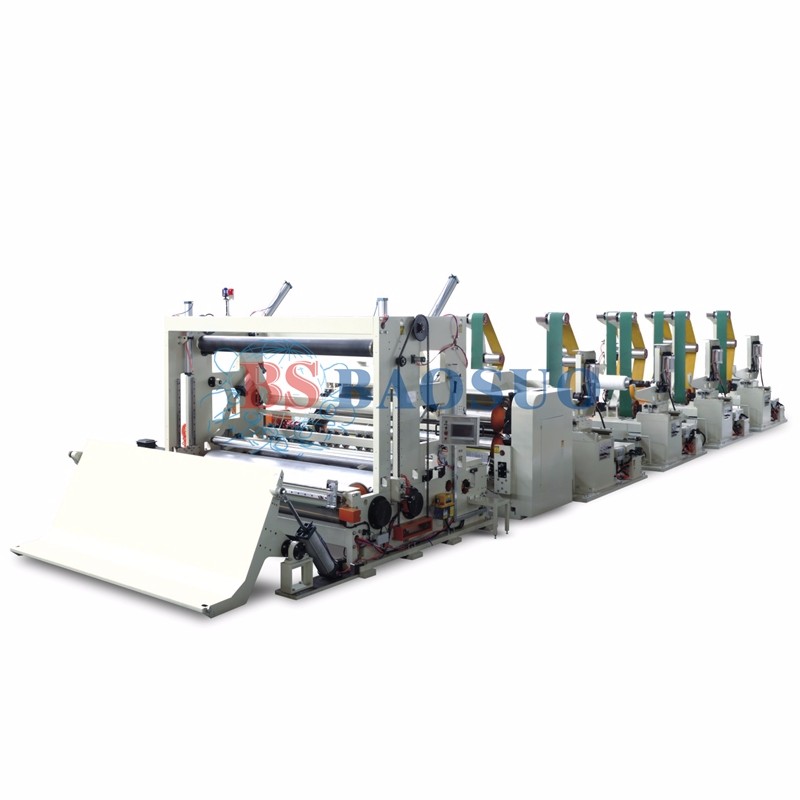

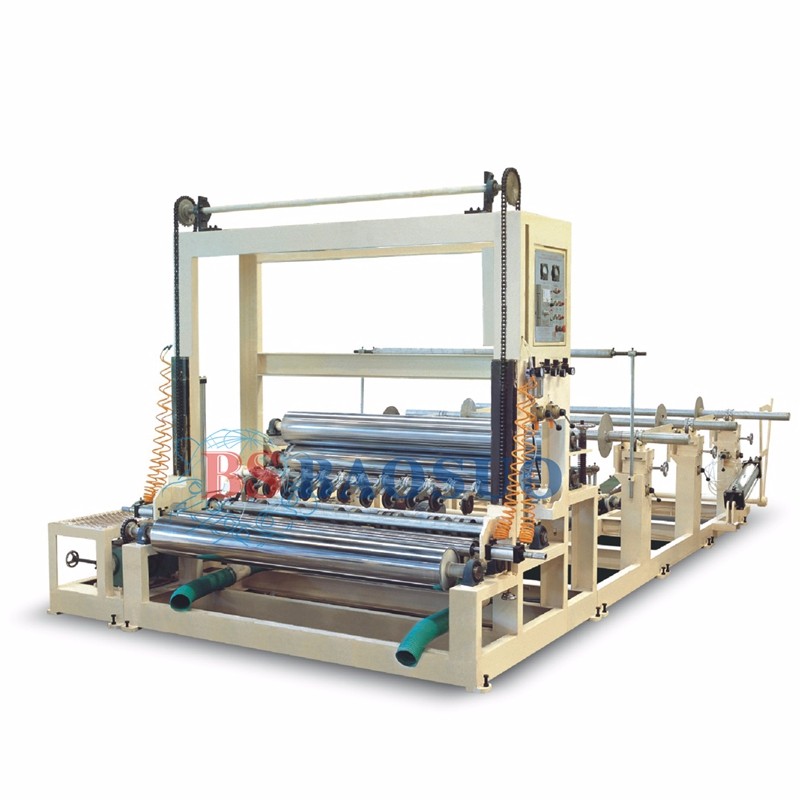

1.Stable production speed up to 250 m/min;

2.Made by quality steel with compact structure;

3.Independent servo motor drive, precise and efficient;

4.Unique control technology, the jumbo roll surface flatness can reach ±0.5 mm;

5. Machine efficiency improved by 15% by adding automation functions in core feeding, web cutting and blowing;

6. High precision closed-loop motion control system consisted of PLC and frequency convertor;

7. Each unwind backstand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8. Dual airbag pressurization controlled calendaring unit.

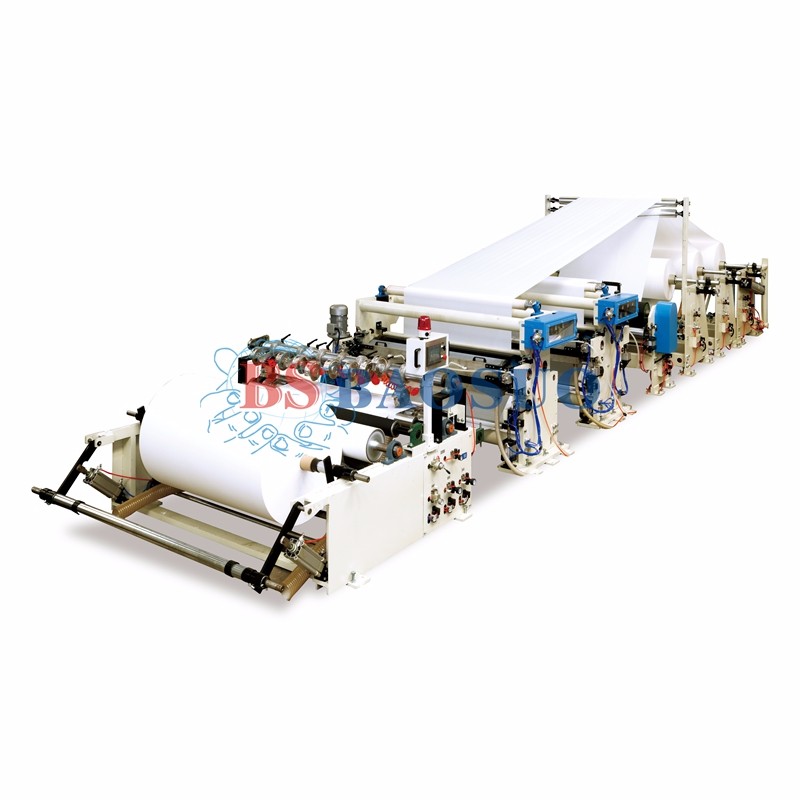

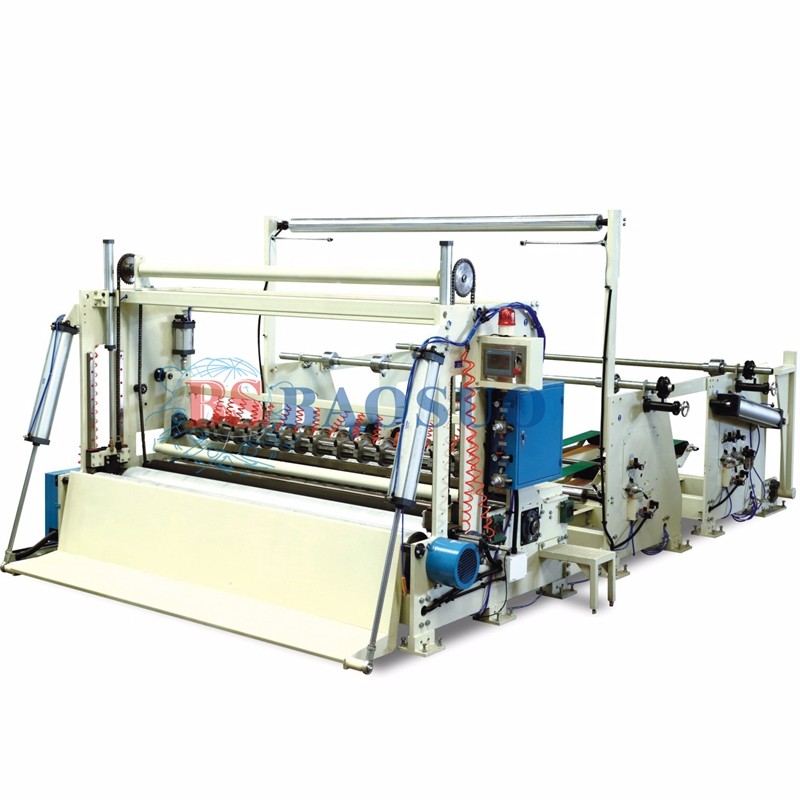

PF-B Automatic Apply Cream Jumbo Roll Slitting Rewinder

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

PF-B | |

Speed | 0 ~ 250 m/min |

Production speed | 200 m/min |

Jumbo roll width | 2850 mm |

Structure | Wall panel |

Jumbo roll diameter | Max. Φ1500 mm |

Jumbo roll core diameter | Φ76.3 |

Unwind stand speed adjustment | Via touch screen to adjust speed of each unwind stand |

Unwind stand left-right position adjustment | Manual adjustment |

Calendaring pressure adjustment | Cylinder pressure, spacing bolt adjusting pressure |

Loading method | Pneumatic loading |

Coating unit | Each set contains one online roller, one coating roller |

Anilox roller | 2900 mm anilox roller should take preservative treatment and valid width2900 mm |

Scraper system | Scraper system takes pneumatic clutch, the spacing of the scraper can be adjustable |

Silting width | Min. width 180 mm, adjustable between min. and max. size |

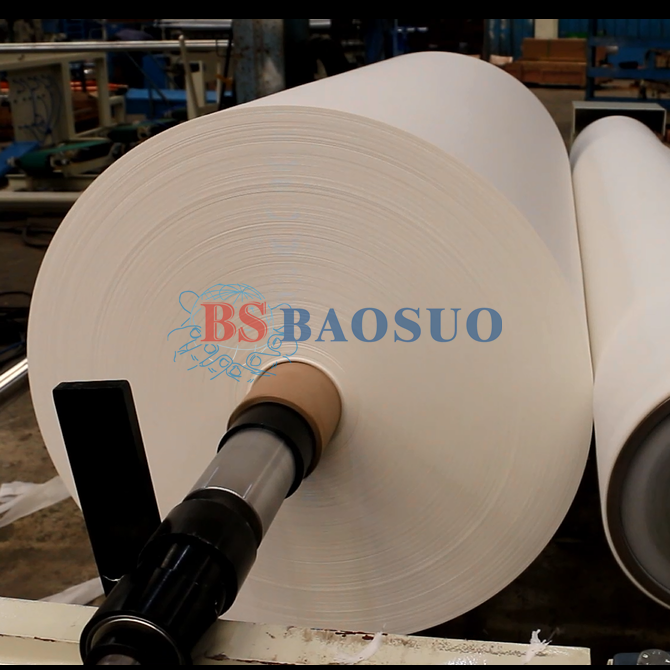

Finished paper size | ≦φ1200 mm diameter |

Finished paper moisture | 15 % ~ 20 % |

Waste paper collecting | Waste paper collector and high-pressure centrifugal fan |

Unwind method | Manual pneumatic control valve |

Driving method | Independent motor |

Protective cover | There is protective covers for main transmission parts |

Power 50kw | 50kw |

Min Compressed air pressure | 0 6Mpa |

Compressed air consumption | 4 m³/hour |