Cheap Facial Tissue Bundle Wrapper wholesale quotes

- BAOSUO

- China

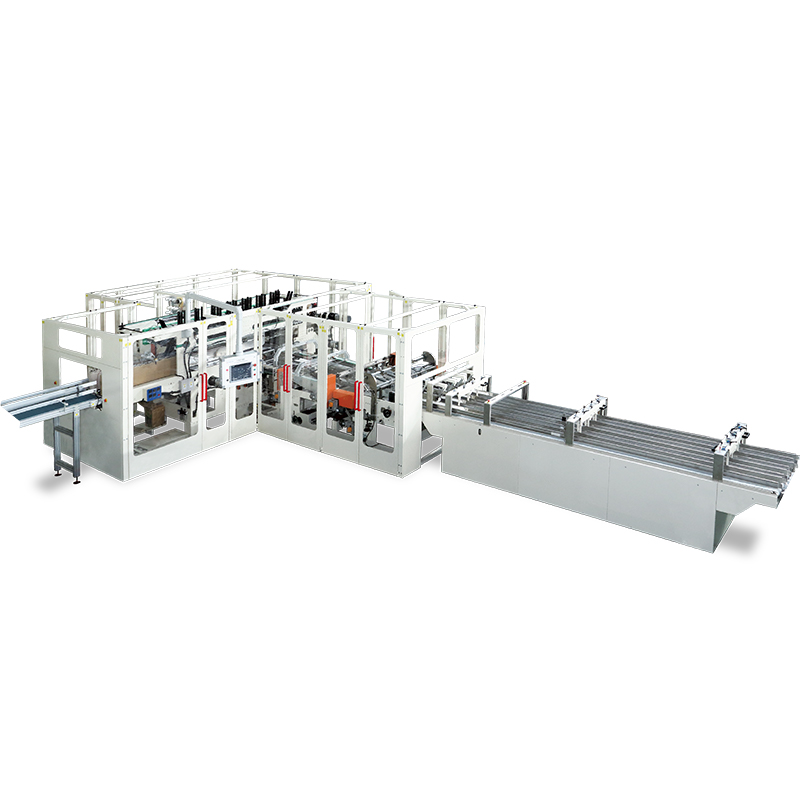

Machine brief introduction

1.This machine can bundle single-packed facial tissue, hand towel, napkin automatically at stable production speed of 35 bundles/min;

2.Double in-feed channels, three bag storage and double pushing arms ensure high speed stable running;

3.Multiple key actions are controlled by servo system, which makes easy operation and convenient maintenance.

4.The sealing adopts the mode of constant heating control and top-battom heating, which will avoid weak sealing and broken sealing, as well as satisfy customer's various requirements on film thickness, inner printing, outer printing, packing material density variation, etc., ensuring strong film adaptability, nice sealing and stable running;

5.This machine is equipped with functions of bag opening protection, non-stop waste bag elimination, air source management, servo overload protection;

6.The output control adopts vacuum belt and air cylinder pressing to avoid rushing;

7.Vacuum shaping is adopted to ensure stable and nice shaping performance;

8.Single row bundling and double row bundling are interchangeable, which makes easy specs switching, convenient operation and high efficiency.

BJ-FW40 Facial Tissue Single Wrapper

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Machine brief introduction

1. This machine can bundle single-packed facial tissue, hand towel, napkin automatically at stable production speed of 35 bundles/min;

2. Double in-feed channels, three bag storage and double pushing arms ensure high speed stable running;

3. Multiple key actions are controlled by servo system, which makes easy operation and convenient maintenance.

4. The sealing adopts the mode of constant heating control and top-battom heating, which will avoid weak sealing and broken sealing, as well as satisfy customer's various requirements on film thickness, inner printing, outer printing, packing material density variation, etc., ensuring strong film adaptability, nice sealing and stable running;

5. This machine is equipped with functions of bag opening protection, non-stop waste bag elimination, air source management, servo overload protection;

6. The output control adopts vacuum belt and air cylinder pressing to avoid rushing;

7. Vacuum shaping is adopted to ensure stable and nice shaping performance;

8. Single row bundling and double row bundling are interchangeable, which makes easy specs switching, convenient operation and high efficiency.

BJ-FW40 | |

Packing speed | Design speed: 40 bundles/min Production speed: 9 ~ 35 bundles/min |

Packing specification | Single row: 1 × 3, 1 × 4, 1 × 5 |

Single product size: L: 125 mm ~ 200 mm W: 95 ~ 105 mm H: 40 mm ~ 100 mm | |

Double row: 2 × 3, 2 × 4, 2 × 5 | |

Single product size: L: 105 mm ~ 160 mm W: 95 ~ 105 mm H: 40 mm ~ 100 mm | |

Pre-made bag installation structure | Hanging symmetric double bag storage |

Pre-made bag storage | ≤ 900 pieces |

Total power | 26 KW |

Compressed air | Compressed air pressure ≥ 0.5 MPA Air source pressure ≥ 360 L/min |

Pre-made bag material | CPP, PE, matt film, complex film |

Machine dimension | 6700 × 2600 × 1850 mm |

Machine weight | 2800 Kg |