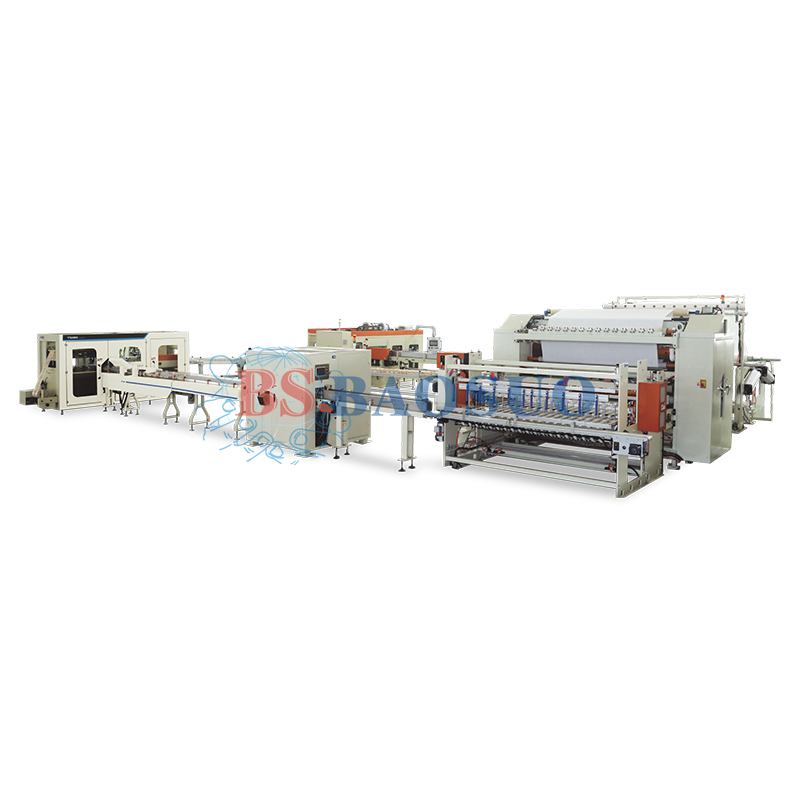

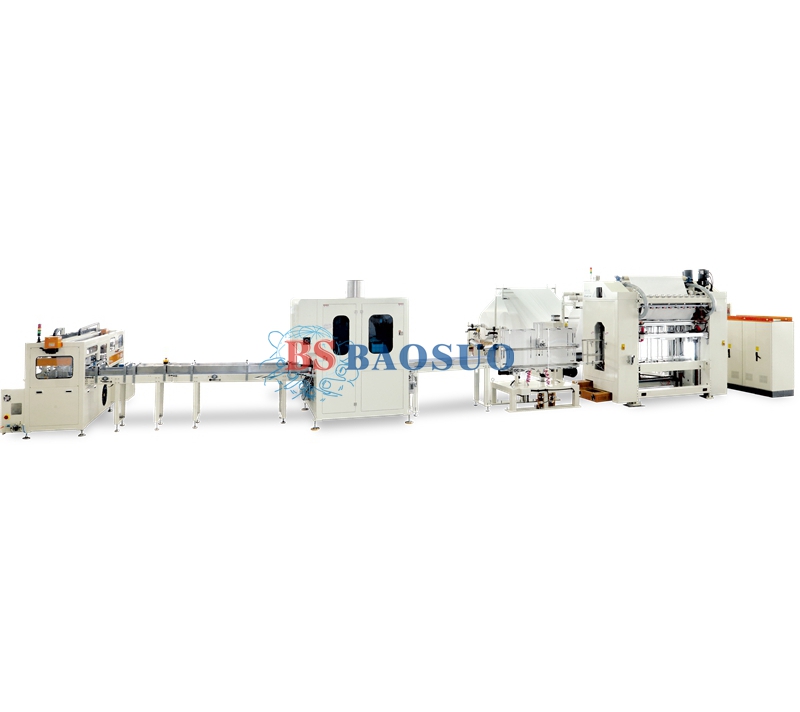

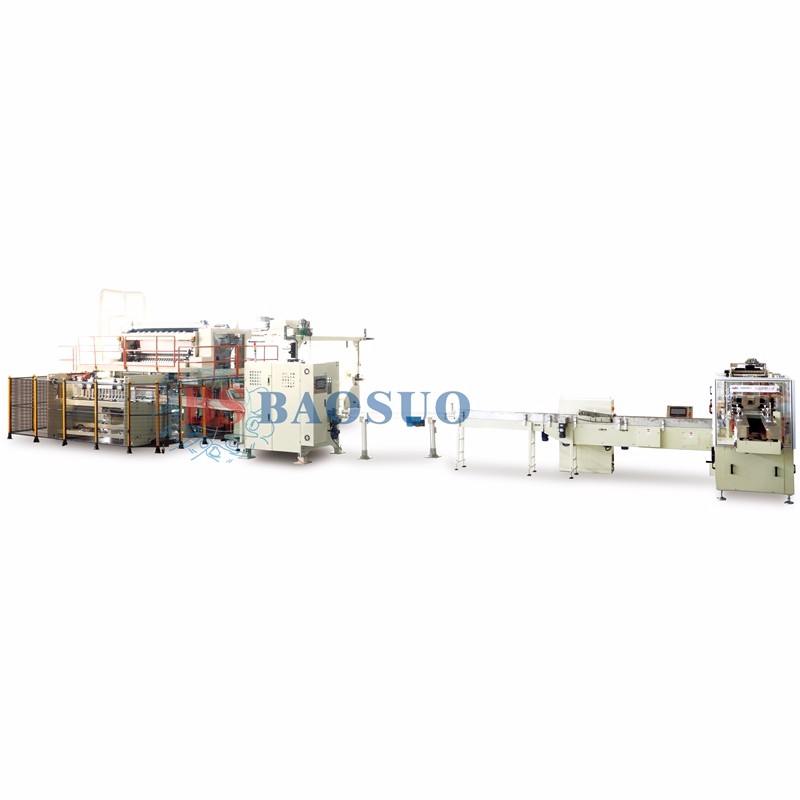

YH-FG Automatic Facial Tissue Production Line

- BAOSUO

- China

YH-FG Automatic Facial Tissue Converting Machine

1. Production speed: 130m/min, stacking speed ≥15log/min, width: 1500-3700mm;

2. The first piece of tissue is folded to the middle automatically, matching the conveyance flip system, and the finished product is beautiful and square;

3. The facial tissue machine is perfectly matched with high value-added products such as position embossing, glue free lamination, 4D embossing and water lamination;

4. Full servo automatic stacking, integrated control, high degree of automation, with function of remote detection;

5. Electromechanical integrated control technology, automatic detection, accurate feedback;

6. Upgraded arc stacking system to improve quality and efficiency.

YH-FG Automatic Facial Tissue Production Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Product description:

YH-FG facial tissue folding machine | |

Design speed | 150 m/min |

Production speed | 130 m/min |

Transfer speed | 15log/min |

Machine width | 1500-3700mm |

Transfer control | Servo motor, integrated control |

The first fold | Servo drive center fold |

Counting mode | Encoder counting |

Counting range | 50 - 250ply |

Flip way | Unique creation conveyor staggered flip |

Transmission metho | Independent motor drive |

Finished product transfer | Automatic |

Highlights of YH-FG Automatic Facial Tissue Production Line

1. Production speed: 130m/min, stacking speed ≥15log/min, width: 1500-3700mm;

2. The first piece of tissue is folded to the middle automatically, matching the conveyance flip system, and the finished product is beautiful and square;

3. The tissue paper machine is perfectly matched with high value-added products such as position embossing, glue free lamination, 4D embossing and water lamination;

4. Full servo automatic stacking, integrated control, high degree of automation, with function of remote detection;

5. Electromechanical integrated control technology, automatic detection, accurate feedback;

6. Upgraded arc stacking system to improve quality and efficiency.