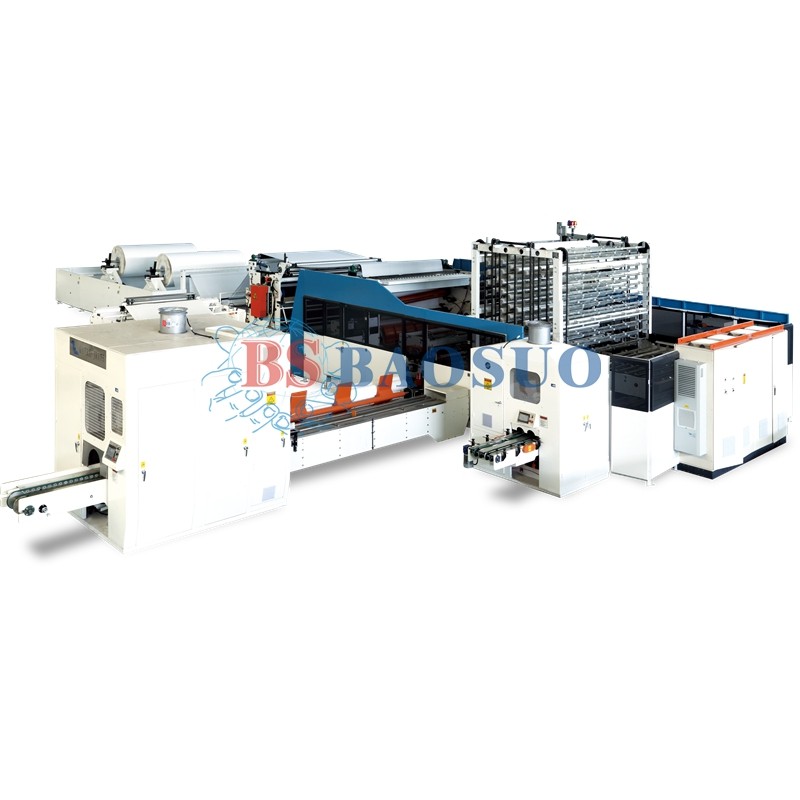

Automatic Start Stop Toilet Roll Kitchen Towel Machine

- BAOSUO

- China

Brief Introduction:

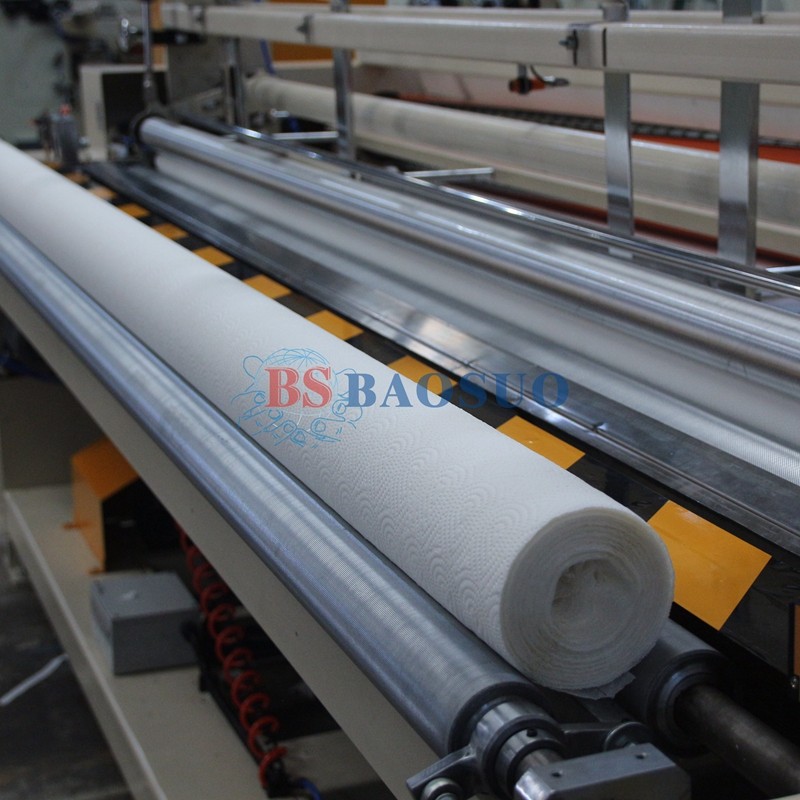

1.Start-stop type with production speed up to 180 m/min;

2.Capable to produce rolls with core or without core;

3. Machine equipped with automation functions in core feeding, web cutting, and blowing;

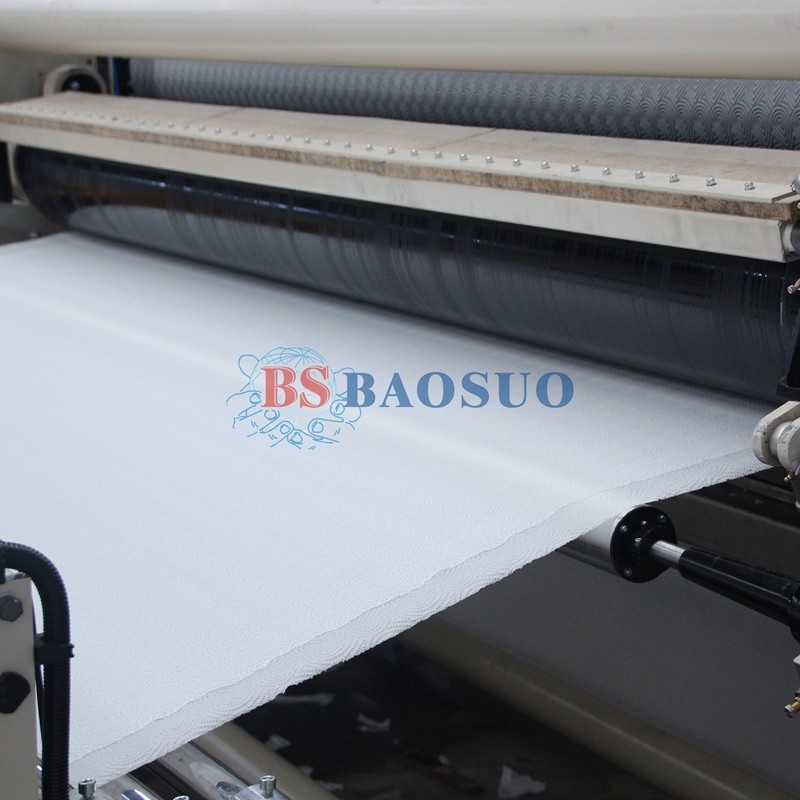

4. Equipped with embossing lamination unit for production of toilet roll and kitchen towel;

5. Option available for auto unload, connection with log saw for production line;

6. Airbag pressurization edge embossing unit is optional;

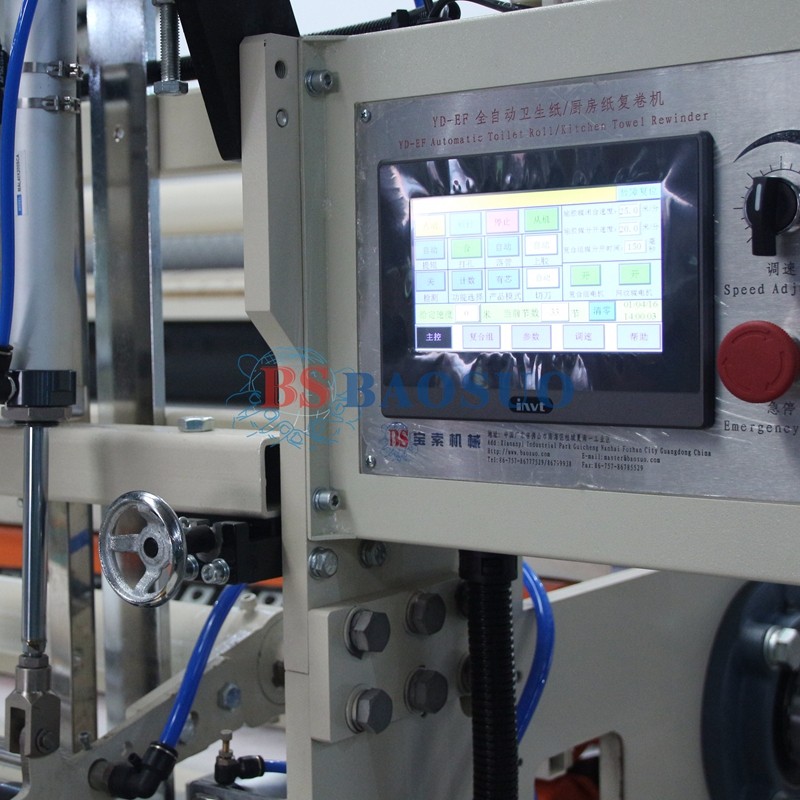

YD-EF Automatic Toilet Roll / Kitchen Towel Rewinder

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Product description:

YD-EF | ||||||

Machine Model | 1570 | 2000 | 2200 | 2600 | 2800 | 2900 |

Raw Material Width | 1750 | 1950 | 2150 | 2550 | 2750 | 2850 |

Finished Roll Diameter | Φ70 ~ 135 (Tightness adjustable) | |||||

Finished Roll Core Diameter | Φ32 ~ 50 | |||||

Raw Material Diameter | Φ1100 mm (Other sizes to be specified) | |||||

Core Size of Jumbo Roll | Φ76.2 mm (Other sizes to be specified) | |||||

Perforation Pitch | 4 perforating blade 110mm; 2 perforating blade 220mm; Gear box adjustment (option) | |||||

Machine speed | 200 m/min | |||||

Perforating Unit | Pneumatic control | |||||

Programmable controller | MITSUBISH Programmable Controller (PLC) | |||||

Unwind stand | 1 ~ 2 ply | |||||

Pneumatic System | 3 HR air compressor Mini Pressure 5 kg/cm² Pa (Provided by client) | |||||

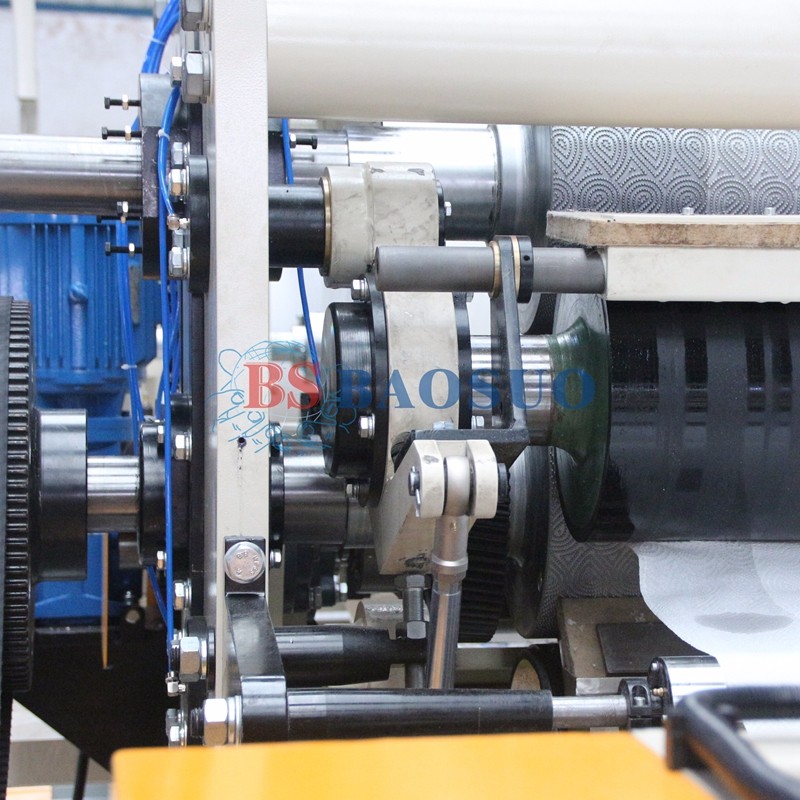

Power | Frequency conversion speed regulator, 11 ~ 24 kw Depend on the model and configuration | |||||

Option | ||||||

Driving system | Individual motor driving | |||||

printing Unit | 1 ~ 2 color printing unit | |||||

Brief Introduction:

1. Start-stop type with production speed up to 180 m/min;

2. Capable to produce rolls with core or without core;

3. Machine equipped with automation functions in core feeding, web cutting, and blowing;

4. Equipped with embossing lamination unit for production of toilet roll and kitchen towel;

5. Option available for auto unload, connection with log saw for production line;

6. Airbag pressurization edge embossing unit is optional;