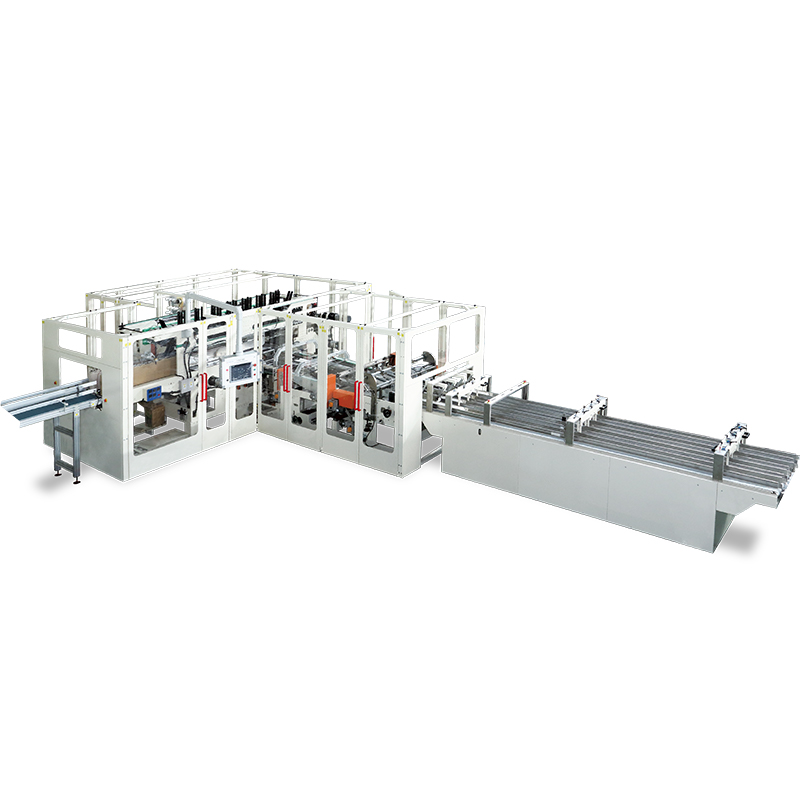

FW35B Facial Tissue Wrapper

- BAOSUO

- China

Machine brief introduction

FW35B Facial Tissue Wrapper is a machine intended for the middle bag facial tissue wrapping.

1. Controlled by 9-axis motion controller. User-friendly. Allow flexibility in operation. Accurate locating. Smoother running.

2. The unique patents of clamping material to enter bag structure solve the problem of material feeding during packaging small packs of paper.

3. Low energy consumption. The rated power of the whole machine is not more than 15KW and the normal production power is not more than 10KW, which is far lower than similar products at home and abroad.

4. The compact design of the whole machine helps save space. And it is convenient for connecting production lines. It can be connected with front single wrapper and back box packing machine to realize the whole process of automatic production.

5. Use well-known components at home and abroad, with mature and stable performance;

6. The equipment has a unique automatic material arranging mechanism, which can realize the fast switching of single and double row product packaging specifications, and the design is convenient for maintenance.

7. The equipment is available to feed bags automatically and accurately, and it will automatically alarm or stop when any bag is detected missing.

8. The heating control adopts a unique constant temperature sealing control method to ensure that the sealing is smooth and perfect.

FW35B Facial Tissue Wrapper

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Machine brief introduction

FW35B Facial Tissue Wrapper is a machine intended for the middle bag facial tissue wrapping.

1. Controlled by 9-axis motion controller. User-friendly. Allow flexibility in operation. Accurate locating. Smoother running.

2. The unique patents of clamping material to enter bag structure solve the problem of material feeding during packaging small packs of paper.

3. Low energy consumption. The rated power of the whole machine is not more than 15KW and the normal production power is not more than 10KW, which is far lower than similar products at home and abroad.

4. The compact design of the whole machine helps save space. And it is convenient for connecting production lines. It can be connected with front single wrapper and back box packing machine to realize the whole process of automatic production.

5. Use well-known components at home and abroad, with mature and stable performance;

6. The equipment has a unique automatic material arranging mechanism, which can realize the fast switching of single and double row product packaging specifications, and the design is convenient for maintenance.

7. The equipment is available to feed bags automatically and accurately, and it will automatically alarm or stop when any bag is detected missing.

8. The heating control adopts a unique constant temperature sealing control method to ensure that the sealing is smooth and perfect.

| FW35B | |

Design production speed | 35 bundles/min |

Packing specification | length 350 mm to 500 mm, width 130 mm to 420 mm height 90 mm to 105 mm |

Pre-made bag material | CPP, PE film, composite film, matte film, the material must be double-sided heat-sealing, the handle hole is the through hole, and the bag has good static elimination and without adhesion phenomenon(Single layer thickness of pre-made bag 40-60μm ) |

| Packing size | 1X3、1X4、1X5、1x6 2X3、2X4、2X5、2X6 |

| Bag storage | ≤ 600 pieces of pre-made bag |

| Machine dimensions | Length: 8844 mm; Width:4050 mm; Height:1630 mm |

| Total power | 15KW |

| Sealing shaping mold | Negative pressure mold forming |

Pre-made bag remaining | The remaining material 25-30mm, and the waste material is automatically sucked into the waste film box |