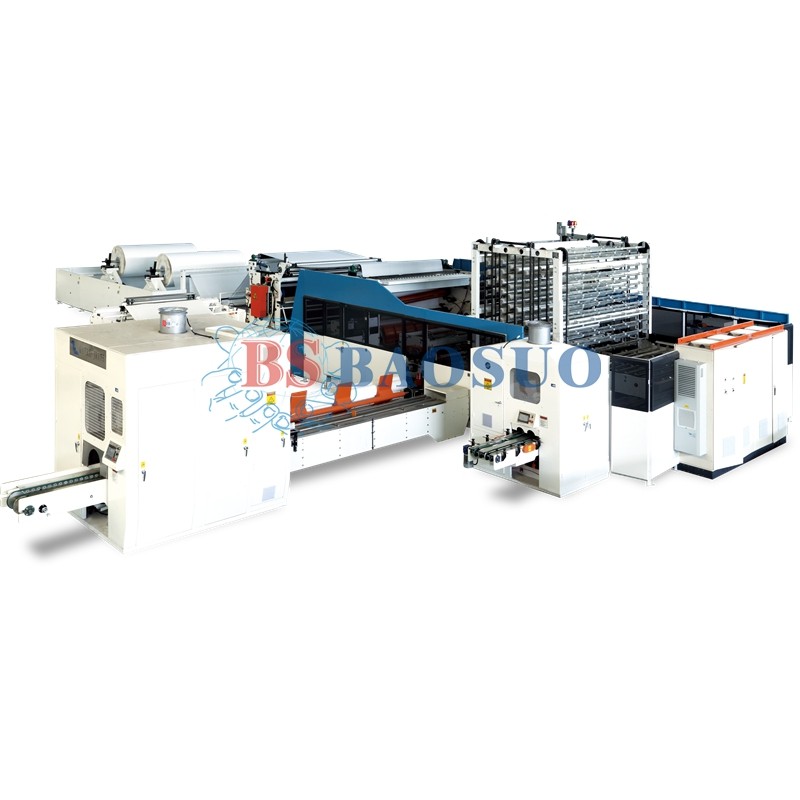

YD-PL300C Coreless Rolls Rewinder Line

- BAOSUO

- China

Brief Introduction of Coreless Toilet Rolls Rewinding Machine:

1.Stable production speed: up to 300 m/min;

2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3.Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability;

5.Flexible and easy handling independent motor drive for each function unit;

6.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination;

7.Equipped with edge embossing unit, 60 embossing wheel for regular web width;

8.Applicable to various web tensions of different jumbo roll grades;

9.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

YD-PL300C Coreless Rolls Rewinder Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Brief Introduction of Coreless Toilet Rolls Rewinding Machine:

1.Stable production speed: up to 300 m/min;

2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3.Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability;

5.Flexible and easy handling independent motor drive for each function unit;

6.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination;

7.Equipped with edge embossing unit, 60 embossing wheel for regular web width;

8.Applicable to various web tensions of different jumbo roll grades;

9.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

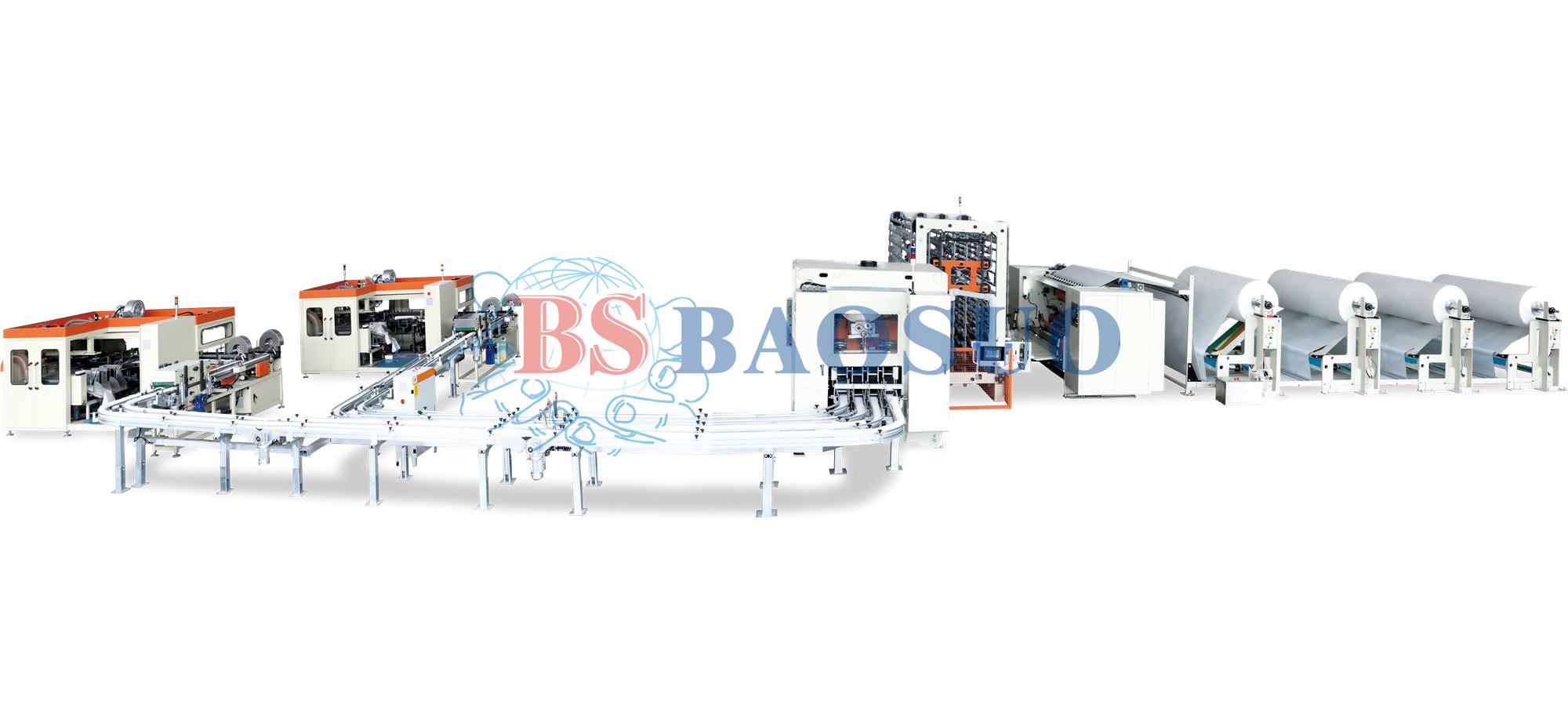

YD-PL300C Coreless Toilet Roll Making Machine | |

Design speed | 300 m/min |

Jumbo roll width | 1750 ~ 2950 mm |

| Production speed | 250m/min, 20logs/min |

Jumbo roll diameter | ≤φ2000 (To be order) |

Jumbo roll core size | φ76.2 mm (Other sizes are available) |

Diamter of finishing log | Φ45 ~ φ110mm |

Control system | PLC |

Web tension system | Encoder, PLC, Inverter |

Backstand | 1 ~ 3 Ply (To be confirmed by client, independent drive) |

Option | |

Embossing unit | Steel to rubber, point to point / nested / DECO embossing lamination system |

Edge embossing unit | Steel to steel |

Printing unit | 1 ~ 2 colors (Customers provides pattern) |