China Facial Tissue Production Line wholesale customized

- BAOSUO

- China

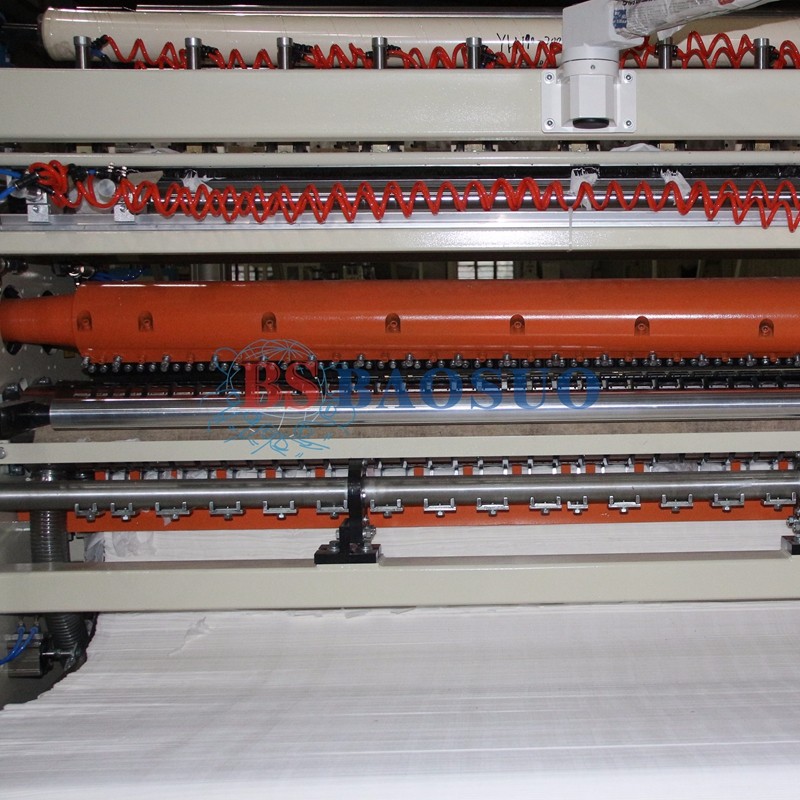

Brief introduction of YH facial tissue folding machine:

1.Stable production speed up to 90 m/min;

2.High precision folding roll to secure performance stability;

3.Excellent suction system with 45 KW low energy consumption vacuum pump;

4.Stable and reliable high speed folder to ensure products to be well folded, tidy and with upscale beautiful appearance;

5.Stable and efficient;

6.opto-mechatronics control technology, automatic broken web detection, and accurate signal feedback;

7.Automatic balance double edge embossing system, cylinder control or airbag control are optional.

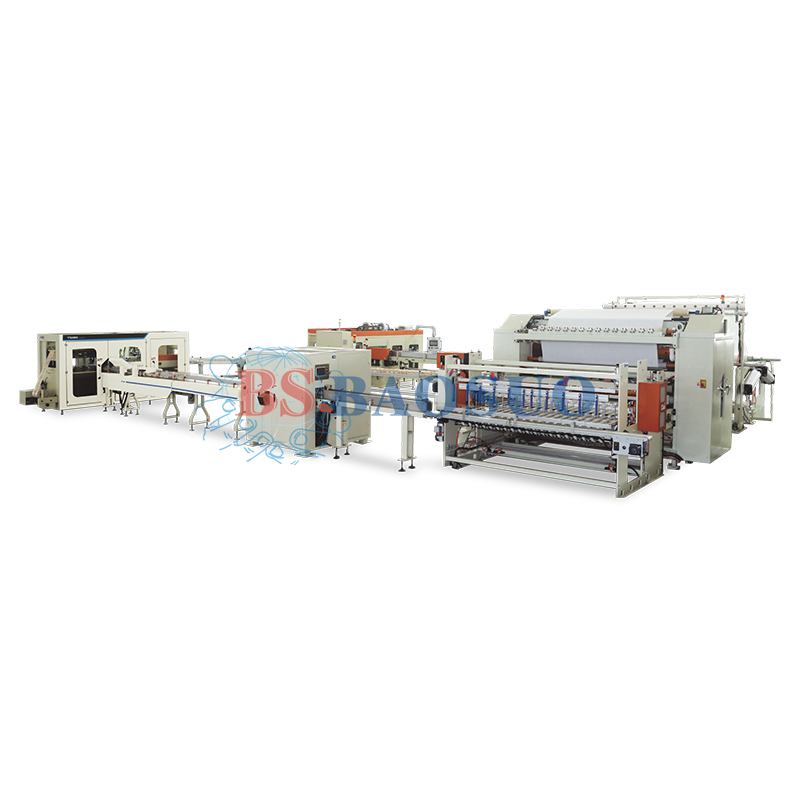

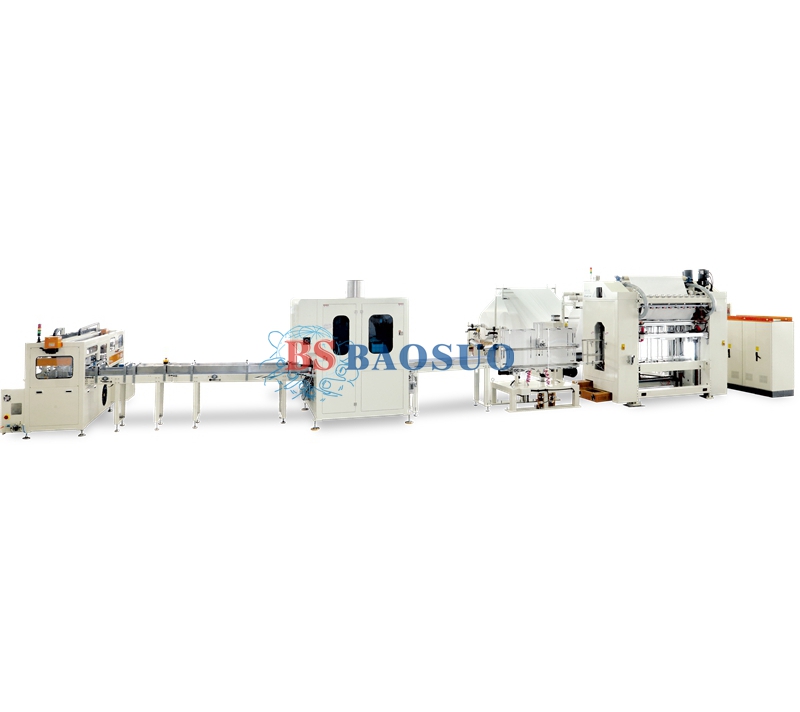

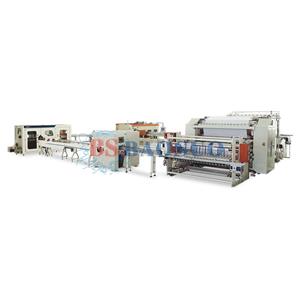

YH Automatic Facial Tissue Economic Production Line (1500~2200)

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Product description(YH economic tissue converting machine):

FOLDING SYSTEM | |

Jumbo roll width | 1500 ~ 2200 mm |

Unfolded size | 190 / 200 ±2 mm |

Folded size | 95 / 100 ±2 mm |

Design speed | 110 m/min |

Production speed | 90 ~ 100 m/min |

Jumbo roll diameter | ≤ 1500 ~ 3000mm (Other size to order) |

Unwind stand | 2 ~ 6 ply, individual driving (To order) |

Folding system | Vacuum suction folding |

Folding type | V fold interfold |

ACCUMULATOR | |

Log quantity | 160 pieces |

Max. unload speed | 15 pieces/min |

LOG SAW CUTTER | ||

Model | FC150-2L | FC200-21 |

Speed | 150 cuts/min | 200 cuts/min |

Feeding channel | Double channels | |

Grinding system | Pneumatic parameter, grinding can be set on control panel | |

Grinding feed | Automatic grinding feeding for circular knife | |

Cutting length | Set on control panel, tolerance ≤ ± 1 mm | |

Cutting vertical tolerance | Tolerance ≤ ± 1 mm | |

length tolerance for two ends | Set on control panel | |

Option | ||

Embossing unit | Steel to steel, steel to rubber | |

Edge embossing unit | Steel to steel | |

Soft type plastic pack | Design conveyor system and soft type plastic packing machine according to production plant | |

Carton box pack | Design conveyor system and carbon box packing machine according to production plant | |