China Automatic Napkin Production Line sale quotes

- BAOSUO

- China

1.Production Speed ≧ 450 m/min, 15 times/min/line;

2.Multiple National patents;

3.Fully automatic, all servomotor folding;

4.Automatic counting, 100% accuracy;

5.Double CPU processing, closed cycle feed back control;

6.Stable running, high efficiency productivity;

7.Automatic last sheet folding (outside the machine);

8.Mechanical, electrical and photoelectric control technology, automatic inspection and feedback.

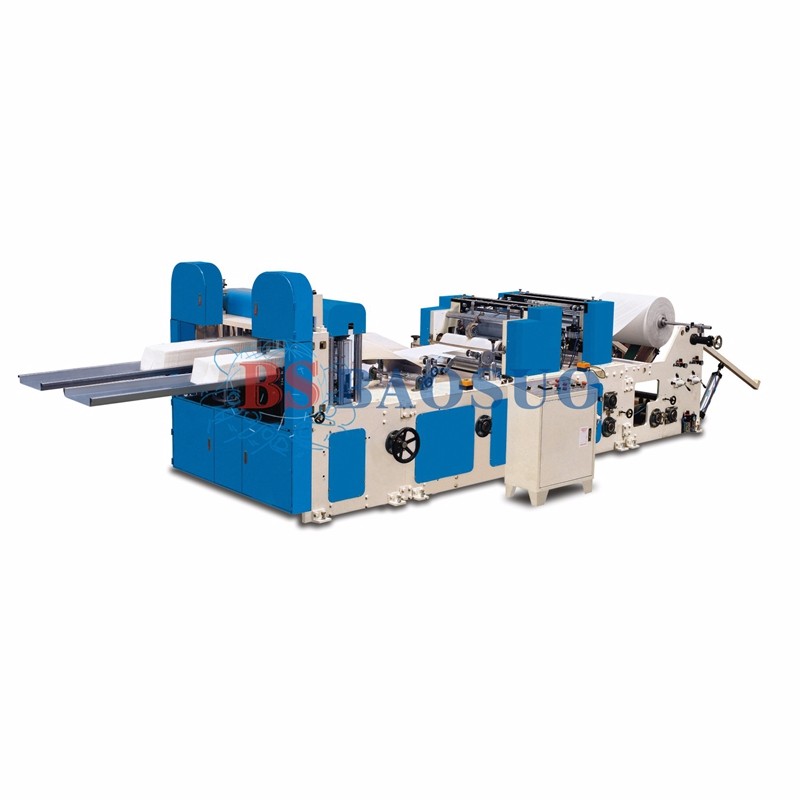

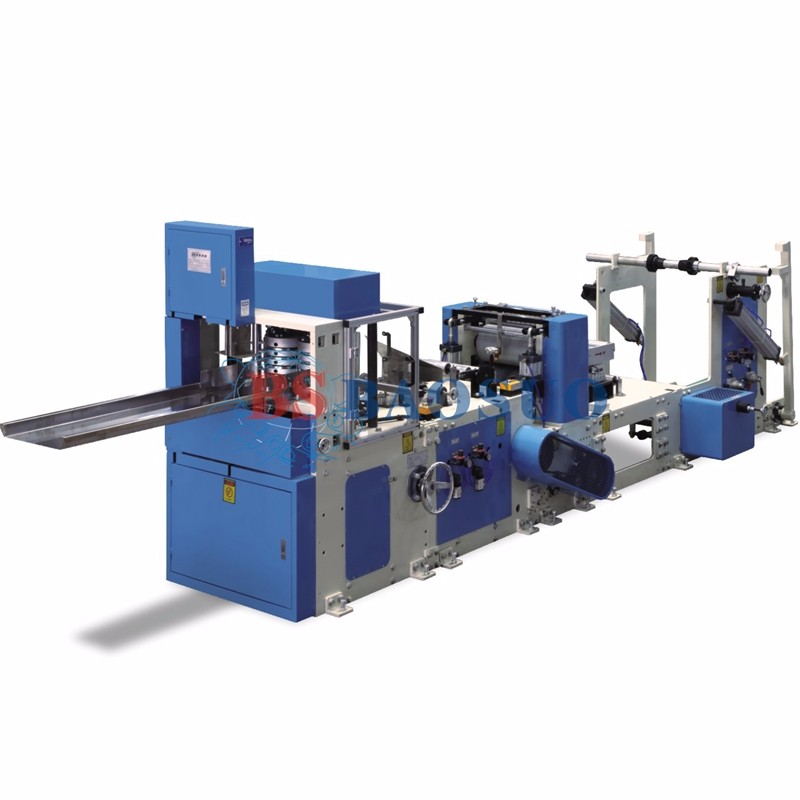

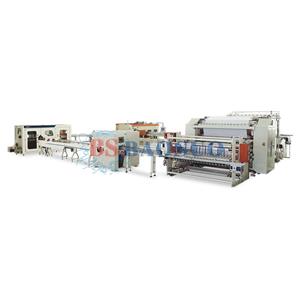

YC-PL Fully Automatic Napkin Production Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

|

YC-PL |

|

|

Jumbo Roll Width |

240 ~ 800 mm |

|

Design Speed |

500 m/min |

|

Folding Type |

Mechanical Folding |

|

Open Size |

240 × 240 ~ 340 × 340 |

|

Folded Size |

120 × 120 ~ 170 × 170 ±2 mm |

|

Jumbo Roll Diameter |

≤ φ2000 mm |

|

Jumbo Roll Core Inside Diameter |

Φ76.2 mm (For other size please special) |

|

Embosser System |

Steel to leather roll, steel to steel |

|

Web Basic Weight (gsm) |

Single layer l5 ~ 30 g/m², 1 ~ 3 Layer |

|

Automatic Transfer Device |

|

|

Transfer Function |

Servo control and photoelectric control lead to automatic transfer. |

|

Sheets Amount Tracking |

High-accuracy servo encoder |

|

Transfer Sheet Count Adjustment |

Seton control panel |

|

Sheet Count Range |

30 ~ 150 sheets |

|

Transfer speed |

Maximum 15 times/min/line |

|

Band Saw Cutting Device |

|

|

Band Saw Size |

4280 * 30 * 0.8 |

|

Grinding Wheel Size |

125 * 20 * 20 / 100 # |

|

Band Saw Sharpening |

Motor-driven.parameter can be set on control panel |

|

Sharpen Dust Suction System |

Dust suction system central zed treatment Sharpen |

|

Packing Machine Parameters |

|

|

Range of Application |

Disposable paper, such as facial tissue, towel, napkin |

|

Packing Material Supply Mode |

ASF-typed fully automatic intelligent material supply |

|

Packing speed |

≤ 70 packs/min |

|

Packing Type |

3D wrapping, sealing on both sides |

|

Paper Length Scope |

100 mm ~ 200 mm |

|

Paper Height Scope |

40 mm ~ 100 mm |

|

Paper Width Scope |

95 mm ~ 105 mm |

|

Overall Size |

Length 5370 mm, Width 3630 mm, Height 1850 mm |

|

Weight |

≦ 2500 KG |

|

Maximum Diameter of Film Roll |

450 mm |

|

Core Diameter of Film Roll |

75 mm |

|

Maximum Width of Film |

340 mm |

|

Film Type |

0.035 ~ 0.05 mm CPP two side sealable film, OPP / CPP double-layer composite film |

|

Embosser Device |

|

|

Embosser Speed Adjustment |

Set on control panel |

|

Embosser Roll Material |

High-strength alloy steel with special treatment |

|

Pressurizing Mode |

Hydraulic |

|

Lubrication Mode |

Gear oil lubrication |

1. Production Speed ≧ 450 m/min, 15 times/min/line;

2. Multiple National patents;

3. Fully automatic, all servomotor folding;

4. Automatic counting, 100% accuracy;

5. Double CPU processing, closed cycle feed back control;

6. Stable running, high efficiency productivity;

7. Automatic last sheet folding (outside the machine);

8. Mechanical, electrical and photoelectric control technology, automatic inspection and feedback.