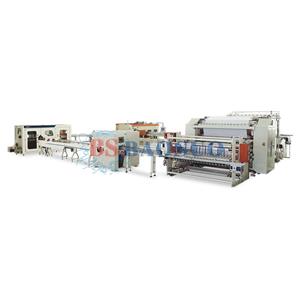

FC220-1L Facial Tissue Log Saw

- BAOSUO

- China

FC220 Facial tissue log saw machine

1.The dics blade structure of the machine adopts a side-cut fixed non-adjustable structure without moving arm structure. Therefore, the dics blade structure runs smoothly and stably. The conveyor part uses a synchronous belt structure. The flat belt structure is canceled to ensure the accuracy of paper feeding. The paper will not slip. The stable speed of the whole machine can reach 150-200 cuts / minute (depending on different paper lengths and different cutting modes).

2.The machine sets three modes, cutting head and tail mode, cutting head mode and non-cutting head and tail mode, which can meet the requirements of small and medium-sized manufacturers. The parameter setting is simple, customers only need to select the suitable cutting mode , and then in the corresponding mode The paper length specification can be set below, and there are few setting parameters, which is convenient and easy to understand.

3.The blade-grinding structure is simple and stable. Customers only need to set the grinding interval and grinding wheel feeding time on the touch screen according to the quality of the paper.

4.All-round safety protection of the whole machine, each door is equipped with a safety switch, and there is an iron mesh at the bottom of the plexiglass to prevent the blade from flying out.

5.The dics blade is imported from German brand TKM, the blade is durable, and other key moving parts are made of high-quality imported bearings.

6.Customers can choose to remove waste paper in the machine or blow out paper out of the machine according to their own requirements.

7.The built-in rack of the electric box can greatly save the space. The pneumatic adjustments are all set on the outer cover of the rack. The adjustment is convenient be done. There is no need to stop the machine to open the safety door to enter the rack,which can ensure the safety of personnel.

FC220-1L Tissue Log Saw Machine

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Brief introduction of facial tissue cutting machine

1.The dics blade structure of the machine adopts a side-cut fixed non-adjustable structure without moving arm structure. Therefore, the dics blade structure runs smoothly and stably. The conveyor part uses a synchronous belt structure. The flat belt structure is canceled to ensure the accuracy of paper feeding. The paper will not slip. The stable speed of the whole machine can reach 150-200 cuts / minute (depending on different paper lengths and different cutting modes).

2.The machine sets three modes, cutting head and tail mode, cutting head mode and non-cutting head and tail mode, which can meet the requirements of small and medium-sized manufacturers. The parameter setting is simple, customers only need to select the suitable cutting mode , and then in the corresponding mode The paper length specification can be set below, and there are few setting parameters, which is convenient and easy to understand.

3.The blade-grinding structure is simple and stable. Customers only need to set the grinding interval and grinding wheel feeding time on the touch screen according to the quality of the paper.

4.All-round safety protection of the whole machine, each door is equipped with a safety switch, and there is an iron mesh at the bottom of the plexiglass to prevent the blade from flying out.

5.The dics blade is imported from German brand TKM, the blade is durable, and other key moving parts are made of high-quality imported bearings.

6.Customers can choose to remove waste paper in the machine or blow out paper out of the machine according to their own requirements.

7.The built-in rack of the electric box can greatly save the space. The pneumatic adjustments are all set on the outer cover of the rack. The adjustment is convenient be done. There is no need to stop the machine to open the safety door to enter the rack,which can ensure the safety of personnel.

FC220-1L Tissue Cutting Machine | |

Cutting dimension (L × W × H) | L = 90 ~ 220 mm W =80 ~ 110 mm H =20 ~ 130 mm(pressing height) H =30 ~190 mm(feeding height) |

Trimming system | Trimming length:15-25mm;PLC controls;operate on touch screen |

Driving system | Servo motor drives |

Cutting system | Rotating circular knife ,sidecut motion |

| Cutting lane | 1 lane |

| Design speed | 220 cuts/min, 1 lane/cut |

Production speed | 150-200 cuts/min, depends on log length and cutting type |

Grinding | Pneumatic grinding. parameter can be set on the touch screen |

Grinding feeding | Automatic feeding grinding for circular knife |

Cutting length adjust | Setting on touch screen, tolerance is ±1 mm |

Knife vertical tolerance | ±1 mm tolerance |