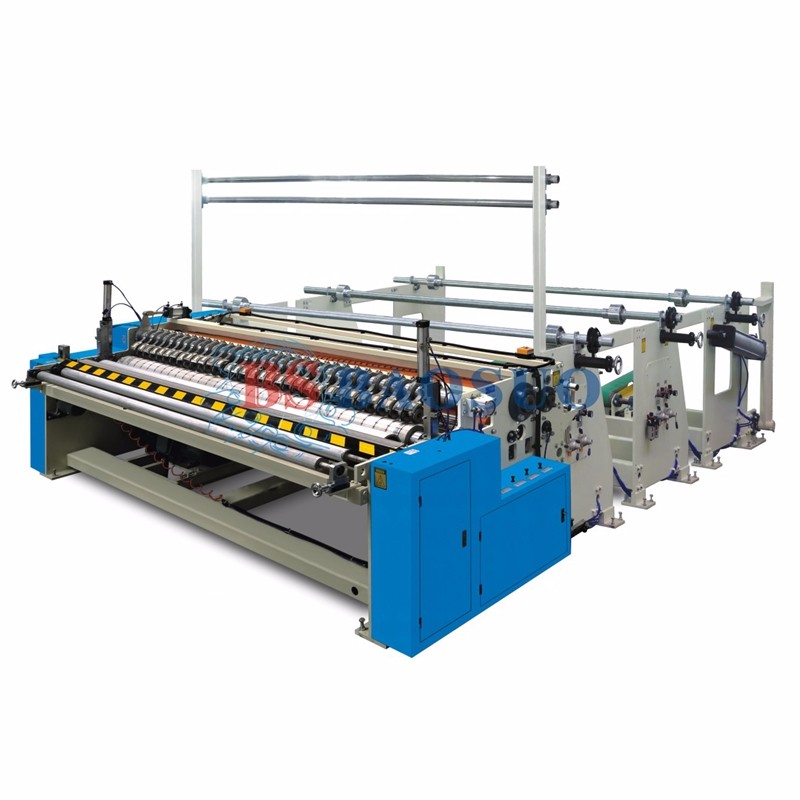

China Automatic Start Stop JRT Rewinder wholesale supplier

- BAOSUO

- China

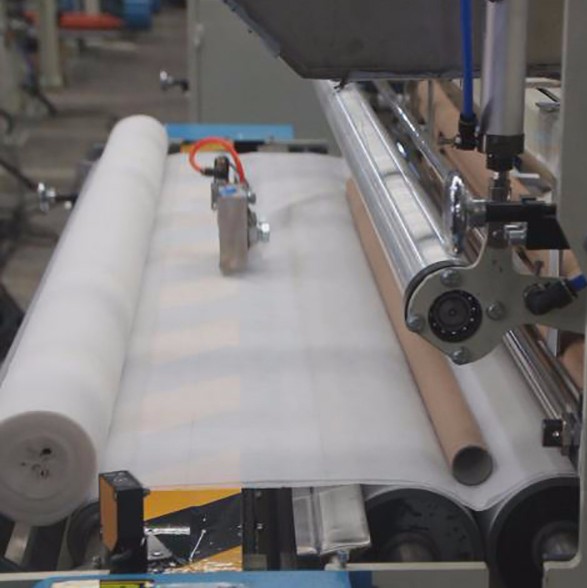

1.Start-stop type, production speed up t0 200 m/min;

2.PLC control system with HMI;

3.Finished roll diameter φ150 mm ~ φ300 mm, core diameter φ40 mm ~ φ80 mm;

4.Main machine in wall panel structure and compact design;

5.Machine equipped with automation functions in core feeding, web cutting, and blowing;

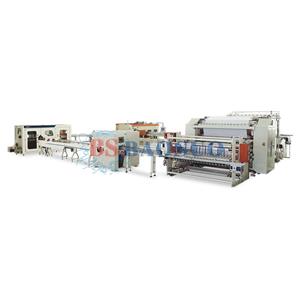

6.Combined production line by adding automatic log discharging function and cutting machine is optional;

7.Airbag pressurization edge embossing unit is optional;

8.Embossing lamination, single embosser or double embosser is optional;

9.Independent motor frequency conversion drive and speed control function is optional. Whole machine is upgraded to wall panel structure, and jumbo roll max. diameter up to φ1500 mm.

YD-CA Automatic JRT Rewinder

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

YD-CA | |||||||

Machine model | 1575 | 2000 | 2200 | 2600 | 2800 | 2900 | 3000 |

Raw material width | 1750 | 1950 | 2150 | 2550 | 2750 | 2850 | 2950 |

Finished roll diameter | Φ150 ~ 300 mm (tightness adjustable) | ||||||

Raw material diameter | Φ1100 mm (Other size are available) | ||||||

Core size of jumbo roll | Φ76.2 mm (Other size are available) | ||||||

Machine speed | 200 m/min | ||||||

Finished roll core diameter | Φ40 ~ 80 mm | ||||||

Unwind stand | 1 ~ 2 ply | ||||||

(L × W × H) Diameter | Depend on the model and configuration | ||||||

1. Start-stop type, production speed up t0 200 m/min;

2. PLC control system with HMI;

3. Finished roll diameter φ150 mm ~ φ300 mm, core diameter φ40 mm ~ φ80 mm;

4. Main machine in wall panel structure and compact design;

5. Machine equipped with automation functions in core feeding, web cutting, and blowing;

6. Combined production line by adding automatic log discharging function and cutting machine is optional;

7. Airbag pressurization edge embossing unit is optional;

8. Embossing lamination, single embosser or double embosser is optional;

9. Independent motor frequency conversion drive and speed control function is optional. Whole machine is upgraded to wall panel structure, and jumbo roll max. diameter up to φ1500 mm.