China Mini-Hanky Production Line sale quotes

- BAOSUO

- China

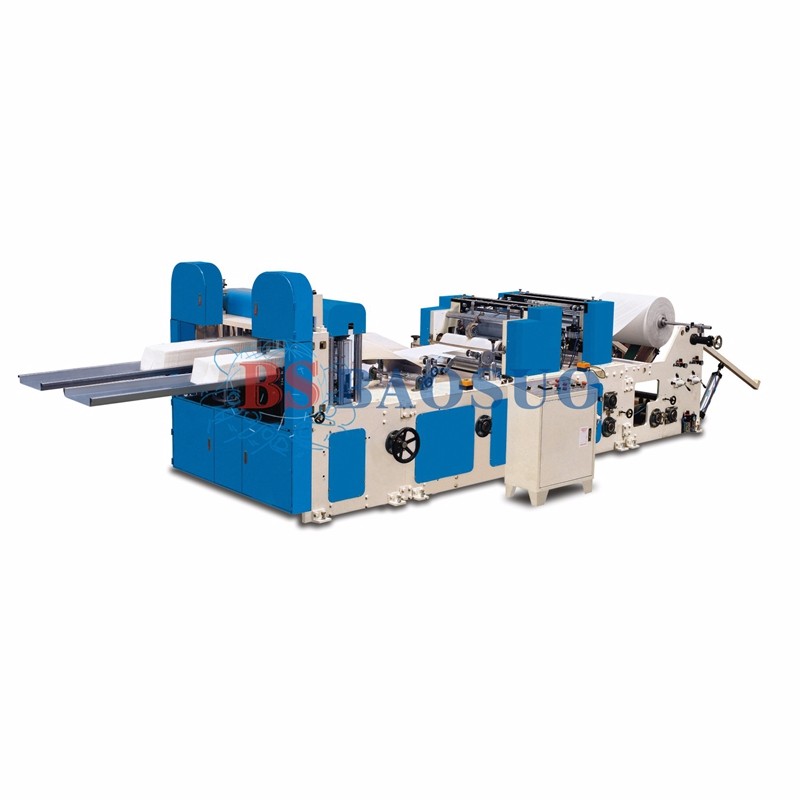

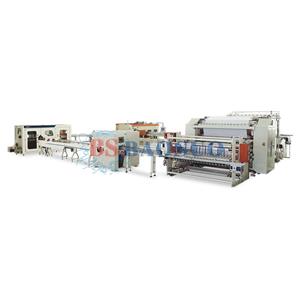

1.Stable production speed up to 1200 sheets/min, with printing unit, 1/4 folding;

2.High automation, opto-mechatronics control technology, and automatic stop when tissue winding around embossing roll;

3.Steel to paper embossing roll with pneumatic pressurization function. Double embossing unit, steel to rubber and steel to felt embossing rolls are optional;

4.Two colors close chamber printing unit. Optional: ordinary printing unit by ink vibrator, or one color printing.

5.Main transmission parts and folding unit with safety cover;

6.Application to various raw paper, and napkins with various specification and grades.

MJ-PL Fully Automatic Mini-Hanky Production Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

MJ-PL | ||

Model | MJ-PL150 | MJ-PL250 |

Backstand | 2 sets | |

Width of jumbo roll | 205 ~ 210 mm | 420 mm |

Tolerance | 205 mm × 208 mm ± 1.5 mm | 203 mm × 208 mm ± 1.5 mm |

Diameter of jumbo roll | Max. 1500 mm | |

Jumbo roll core inner diameter | 76.2 mm | |

GSM of raw paper (2 ply) | 18 ~ 20 g/cm² | 17 ~ 18 g/cm² |

GSM of raw paper (3 ply) | 13 ~ 26 g/cm² | 14 ~ 16 g/cm² |

GSM of raw paper (4 ply) | 12 ~ 14 g/cm² | 12 ~ 14 g/cm² |

Finished product’s diameter (72 mm × 53 mm × 25 mm) | ±2 | ± 1.5 mm |

Finished product’s diameter (110 mm × 53 mm × 25mm) | ±2 | ± 1.5 mm |

Design speed | 1300 sheets/min | 2500 sheets/min |

Production speed (3 ply) | 1200 sheets/min | 2300 sheets/min |

Paper feeding system | BST web guiding system | |

Embossing device | Pneumatic calendaring, steel to steel embossing | |

Packing sheet | 10 or 8 sheets/bag | 10 sheets/bag |

Packing film orientation | Electrical control | |

Packing film thickness | 0.04 ~ 0.05 mm PE or CPP (ATTN: raw material for single pack should be different from medium pack) | |

Film diameter | 380 mm (Max.: 380 mm) | |

Paper feeder | 10 sets linkages | |

Packing sealing | Heat sealing 220 V, 1000 W (150 mm × 180 mm × 2 pieces) (30 mm × 1100 mm × 2 pieces) | |

Design speed | 130 bags/min (10 sheets/bag) | 250 bags/min (10 sheets/bag) |

Production speed | 120 bags/min (10 sheets/bag) | 230 bags/min (10 sheets/bag) |