folding machine

-

Hot

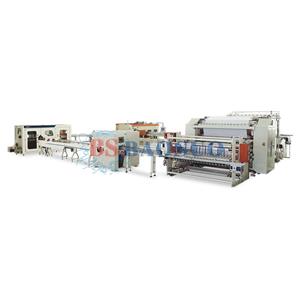

MJN-PL automatic transfer paper hand towel production line

MJN-PL Automatic Hand Towel Paper Machine 1. Machine width: 2800mm 2. HIgh production speed and stable: 225m/min

Email Details -

Hot

YH-FG Automatic Facial Tissue Production Line

YH-FG Automatic Facial Tissue Converting Machine 1. Production speed: 130m/min, stacking speed ≥15log/min, width: 1500-3700mm; 2. The first piece of tissue is folded to the middle automatically, matching the conveyance flip system, and the finished product is beautiful and square; 3. The facial tissue machine is perfectly matched with high value-added products such as position embossing, glue free lamination, 4D embossing and water lamination; 4. Full servo automatic stacking, integrated control, high degree of automation, with function of remote detection; 5. Electromechanical integrated control technology, automatic detection, accurate feedback; 6. Upgraded arc stacking system to improve quality and efficiency.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

Hot

1500mm - 2200mm Auto Transfer Automatic Facial Tissue Production Line

Brief introduction(YH-FD Automatic Facial Tissue Converting Machine): 1.Design speed: 130m/min, stacking speed >13 log/min, width: 1500-2200mm; 2.The first piece of tissue is folded to the middle automatically, matching the conveyance flip system, and the finished product is beautiful and square; 3.Perfect matching with high value-added products such as position embossing, glue free lamination and 4D embossing; 4.Full servo automatic stacking, integrated control, high degree of automation, with function of remote detection; 5.Electromechanical integrated control technology, automatic detection, accurate feedback; 6.Simple structure, simplified process, easy operation and maintenance.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

2900mm - 3600mm Auto Transfer Automatic Facial Tissue Production Line

Brief introduction of YH-PL Automatic Facial Tissue Converting Machine: 1.Stable production speed: up to 150 m/min, minimum 12 logs/min. 2. Core technologies have been granted multiple national patents, and are applying for international patents. 3. High automation, fully servo-controlled folding system with controllable folding motion. 4. Stable and reliable high speed folder to ensure products well folded, tidy and with upscale beautiful appearance. 5. Patent superior vacuum suction technology for web slitting to ensure folding uniformity of facial tissue. 6. Non-stop automatic setting on sheet count,which can be 100% accurate. 7. Pneumatic punching web splicing method, splicing efficiency improved 50% compared to traditional way. 8. The machine has strong adaptability to the different webs and can produce various grades of facial tissue. 9. Dual motion CPU for data processing and closed-loop control signal transient response to ensure fast and stable control. 10. Automatic detecting and accurate feedback by opto-mechatronics control technology.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

2200mm - 2900mm Auto Transfer Automatic Facial Tissue Production Line

Brief introduction of YH-PJ automatic facial tissue converting machine: 1.Production Speed≧100 m/min, with stacking speed of 8 ~ 9 log/min; 2.Core technology has obtained multiple National patents 3.High degree of automation, full servo stacking mode 4.Separation number is automatically sets, with accuracy of 100 % 5.With dual motion CUP for data processing, and closed-loop instantaneous feedback control signal. 6.Stable operation, high production efficiency 7.With function of automatic end folding (outside the machine) 8.Electromechanical integrated control technology, automatic detection, accurate feedback.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

1500mm - 2200mm Automatic Facial Tissue Production Line

Brief introduction of YH facial tissue folding machine: 1.Stable production speed up to 90 m/min; 2.High precision folding roll to secure performance stability; 3.Excellent suction system with 45 KW low energy consumption vacuum pump; 4.Stable and reliable high speed folder to ensure products to be well folded, tidy and with upscale beautiful appearance; 5.Stable and efficient; 6.opto-mechatronics control technology, automatic broken web detection, and accurate signal feedback; 7.Automatic balance double edge embossing system, cylinder control or airbag control are optional.

facial tissue folding machine Facial Tissue Economic Production Line facial tissue folder tissue converting machineEmail Details -

900mm - 1500mm Facial Tissue Folder

Brief introduction of YH Facial Tissue Folding Machine: 1.Stable production speed up to 90 m/min; 2.High precision folding roll to secure performance stability; 3.Excellent suction system with 15 KW low energy consumption vacuum pump; 4.Stable and reliable high speed folder to ensure products to be well folded, tidy and with upscale beautiful appearance; 5.Stable and efficient; 6.opto-mechatronics control technology, automatic broken web detection, and accurate signal feedback; 7.Automatic balance double edge embossing system, cylinder control or airbag control are optional.

Email Details -

400m/minAuto Transfer Automatic Napkin Production Line

1.Production Speed ≧ 450 m/min, 15 times/min/line; 2.Multiple National patents; 3.Fully automatic, all servomotor folding; 4.Automatic counting, 100% accuracy; 5.Double CPU processing, closed cycle feed back control; 6.Stable running, high efficiency productivity; 7.Automatic last sheet folding (outside the machine); 8.Mechanical, electrical and photoelectric control technology, automatic inspection and feedback.

Email Details -

Hot

Automatic N Fold Towel Production Line

MJ-NJ-PJ Automatic N Fold Hand Towel Paper Machine 1. Machine width: 1380-1840mm 2. HIgh production speed and stable: 150m/min

Email Details