making machine

-

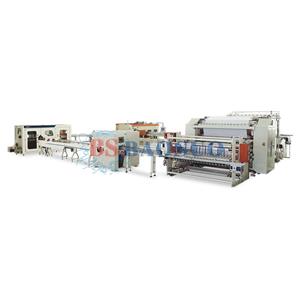

YH-FD Cotton Tissue Production Line

YH-FD Cotton Tissue Cotton Dry Wipes Production Line Making Machine: Stable production speed:60 m/min; Stacking speed:10 log/min 5 servo control to ensure automatic stacking. Intelligent control system makes the operation simply.

Email Details -

1/8 Fold Dinner Napkin Folder

1.MJ-C is without printing (Optional: MJ-D with printing), folding unit normally is quarter turn type. Regular specs: 400, 330 and 300; 2.Stable production speed up to 300 sheets/min, 250 sheets/min when with printing, 1/8 folding. Production speed may vary for different Napkin size; 3.High automation, opto-mechatronics control technology, automatic stop when tissue wind around embossing roll; 4.Easy operating, accurate skip counting by tissue out-feed guide board cylinder; 5.Optional embossing unit: steel to rubber, steel to paper, steel to felt, or others; 6.Ink distributed by ink vibrator, up to 2 colors printing; 7.MJ-D equipped with calendaring unit or deviation rectifying system, jumbo roll diameter up toφ1300 mm; 8.Main transmission parts with safety cover; 9.PLC control system.

Email Details -

Hot

YD-PL300C Coreless Rolls Rewinder Line

Brief Introduction of Coreless Toilet Rolls Rewinding Machine: 1.Stable production speed: up to 300 m/min; 2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 3.Straight in machine web cutting, precise log diameter control system is accurate and easy operating; 4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 5.Flexible and easy handling independent motor drive for each function unit; 6.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination; 7.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 8.Applicable to various web tensions of different jumbo roll grades; 9.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

Coreless toilet rolls Coreless toilet roll making machine toilet roll making machine Coreless toilet rolls rewinding machineEmail Details -

100m/min Automatic High Speed Core Machine

1.Stable production speed: up to 80 m/min; 2.Automatic slitting by servo motor; 3.Length controlled by sensor; 4.Rotation glue roll, automatic separation of raw paper and glue roll when stop.

Email Details -

160m/min Automatic High Speed Core Machine

1.Stable production speed: up to 120 m/min; 2.Automatic slitting by servo motor; 3.Length controlled by sensor; 4.Rotation glue roll, automatic separation of raw paper and glue roll when stop.

Email Details -

Automatic Core Machine

1.Stable production speed 0 ~ 18 m/min; 2.Hydraulic cylinder for automatic core cutting; 3.Magnetic motor for speed adjustment; 4.Core cutting length controlled by sensor; 5.Hydraulic oil cooled down by cycling water is optional.

Email Details -

Hydraulic Core Machine

1.Stable production speed 0 ~ 20 m/min; 2.Hydraulic cylinder for automatic core cutting; 3.Magnetic motor for speed adjustment; 4.Core cutting length controlled by sensor; 5.Hydraulic oil cooled down by cycling water is optional.

Email Details -

Hot

1800m/min Crescent Former Tissue Machine

Brief Introduction of BC-1800 Crescent Former Tissue Machine 1.Steady running 2.Low running cost 3.Paper web forming uniformity 4.High tensile strength 5.Small web basic weight deviation 6.Large output, with daily capacity of each machine up to 135 tons! 7.Intelligent operation, easy maintenance 8.Quick start-up

Email Details