making machine

-

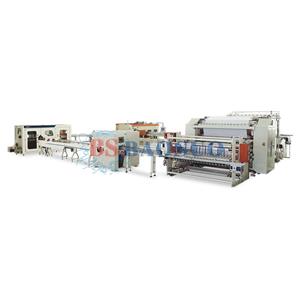

450m/min Non-Stop Toilet Roll Kitchen Towel Machine

Brief Introduction of YD-PL450C Toilet Paper Rewinding Machine: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: the speed of this toilet roll making machine is up to 400 m/min for rolls with core, 250 m/min for coreless; 3.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating; 5.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 6.Flexible and easy handling independent motor drive for each function unit; 7.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination; 8.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 9.Applicable to various web tensions of different jumbo roll grades; 10.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

tissue paper rewinder toilet paper rewinding machine kitchen towel making machine Kitchen Towel RewinderEmail Details -

350m/min Non-Stop Toilet Roll Kitchen Towel Machine

Brief Introduction: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: up to 300 m/min for rolls with core, 250 m/min for coreless roll; 3.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating; 5.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 6.Flexible and easy handling independent motor drive for each function unit; 7.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 8.Applicable to various web tensions of different jumbo roll grades; 9.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

Email Details -

250m/min Non-Stop Toilet Roll Kitchen Towel Machine

Brief Introduction: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: up to 250 m/min for rolls with core, 180 m/min for coreless roll; 3.High automation, integrated control system has strong extension function and supports remote terminal connection and detection; 4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 5.Non-stop rewinding with tissue length error±1 sheet; 6.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 7.Rear doctor blade for web cutting and core gluing,perfect match product with embossing lamination; 8.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

Email Details -

200m/min Non-Stop Toilet Roll Kitchen Towel Machine

Brief Introduction of YD-PL200C Toilet Paper Rewinding Machine: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: up to 200 m/min for rolls with core, 180 m/min for coreless roll; 3.High automation, integrated control system has strong extension function and supports remote terminal connection and detection; 4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 5.Non-stop rewinding with tissue length error±1 sheet; 6.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 7.Rear doctor blade for web cutting and core gluing,perfect match product with embossing lamination; 8.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

tissue paper rewinder toilet paper rewinding machine kitchen towel making machine Kitchen Towel RewinderEmail Details -

1500mm - 2200mm Automatic Facial Tissue Production Line

Brief introduction of YH facial tissue folding machine: 1.Stable production speed up to 90 m/min; 2.High precision folding roll to secure performance stability; 3.Excellent suction system with 45 KW low energy consumption vacuum pump; 4.Stable and reliable high speed folder to ensure products to be well folded, tidy and with upscale beautiful appearance; 5.Stable and efficient; 6.opto-mechatronics control technology, automatic broken web detection, and accurate signal feedback; 7.Automatic balance double edge embossing system, cylinder control or airbag control are optional.

facial tissue folding machine Facial Tissue Economic Production Line facial tissue folder tissue converting machineEmail Details -

BPM Pulp Machine Series

Product Model: BPM Design Speed: 100-500m/min Former Type: Twin wire Dry Type: Hot air dry

Email Details -

2 Line High Speed Napkin Folder

1.Stable production speed up t0 1600 sheets/min, 1/4 folding; 2.High automation, opto-mechatronics control technology and automatic stop when tissue winding around embossing roll; 3.Easy operating, skip counting can be one sheet or designated sheets, with hotkey reset to one sheet skip counting; 4.1/6 folding, 1/8 folding or other folding types are optional; 5.Unwind back stand suitable for jumbo roll diameter up to φ150 0mm. Deviation rectifying unit is optional; 6.Main transmission parts and folding unit are covered by shields; 7.Applicable to various raw paper, and napkins with various specifications and grades.

Email Details -

Hot

Automatic N Fold Towel Production Line

MJ-NJ-PJ Automatic N Fold Hand Towel Paper Machine 1. Machine width: 1380-1840mm 2. HIgh production speed and stable: 150m/min

Email Details -

1 Line High Speed Napkin Folder

1.Stable production speed up to 800 sheets/min, 1/4 folding; 2.High automation, opto-mechatronics control technology, and automatic stop when tissue winding around embossing roll; 3.Easy operating, skip counting can be one sheet or designated sheets, with hotkey reset to one sheet skip counting; 4.1/6 folding, 1/8 folding or other folding types are optional; 5.Unwind back stand suitable for jumbo roll diameter up to φ1500 mm. Deviation rectifying unit is optional; 6.Main transmission parts and folding unit with safety cover; 7.Applicable to various raw paper, and napkins with various specifications and grades.

Email Details